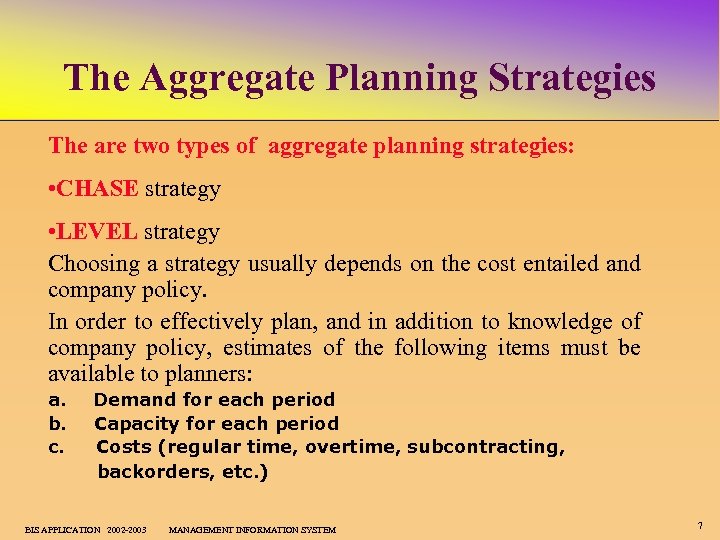

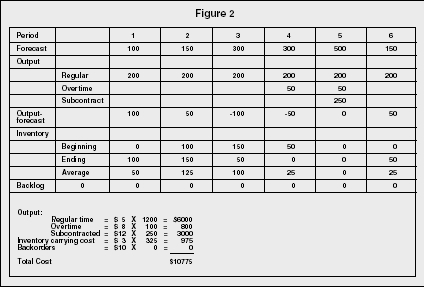

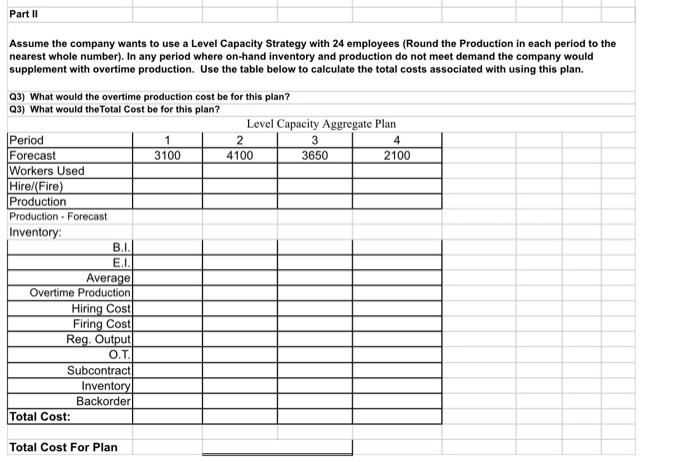

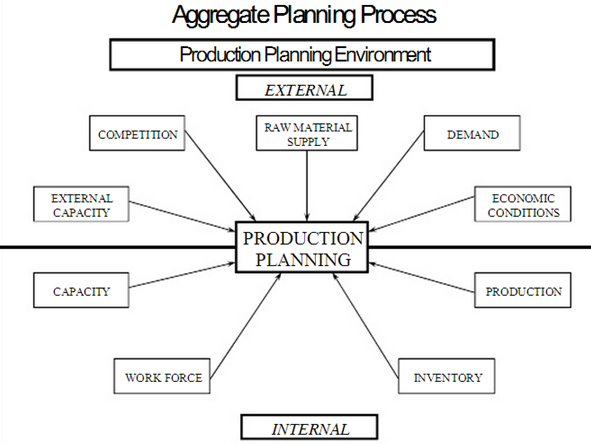

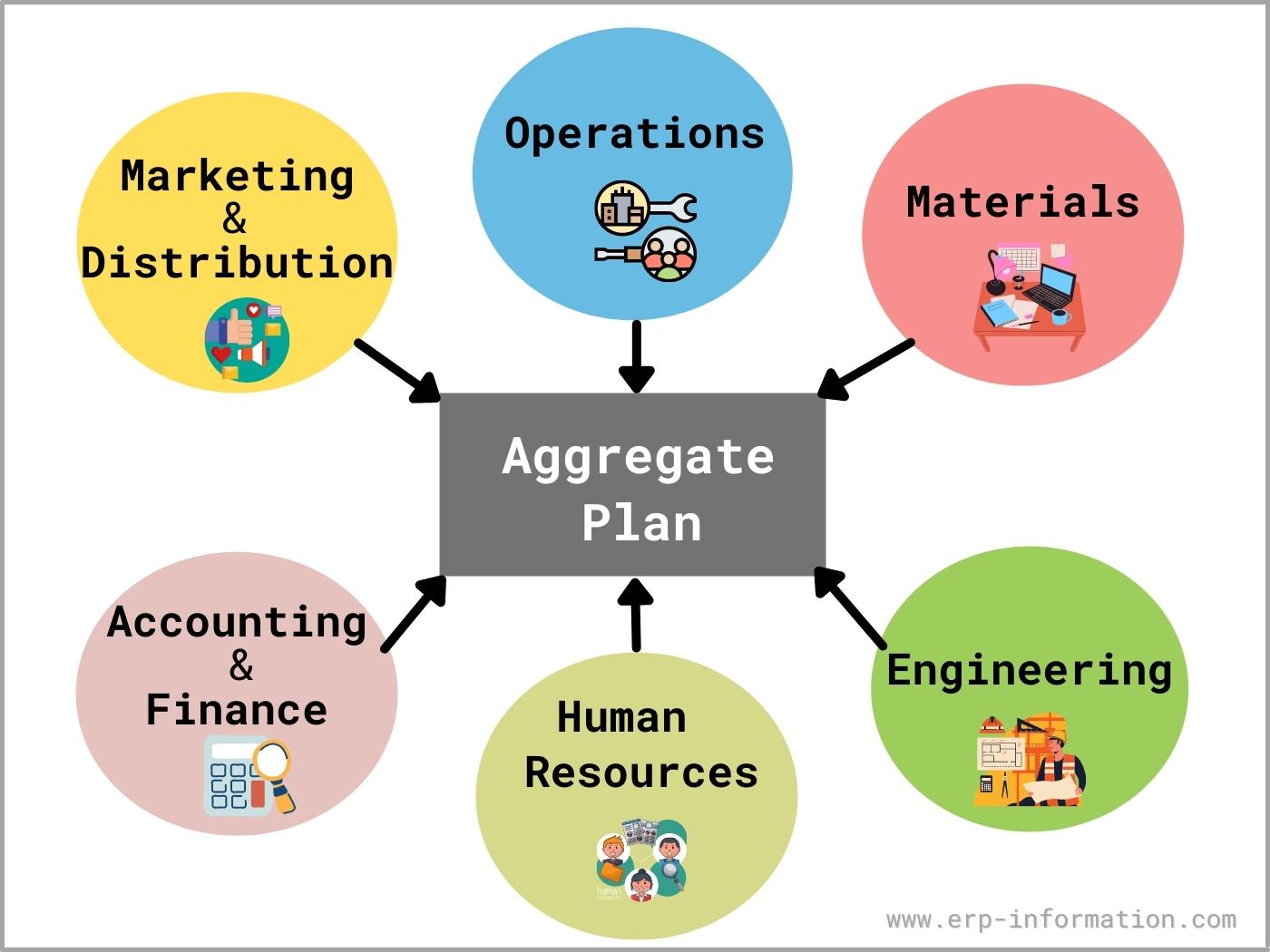

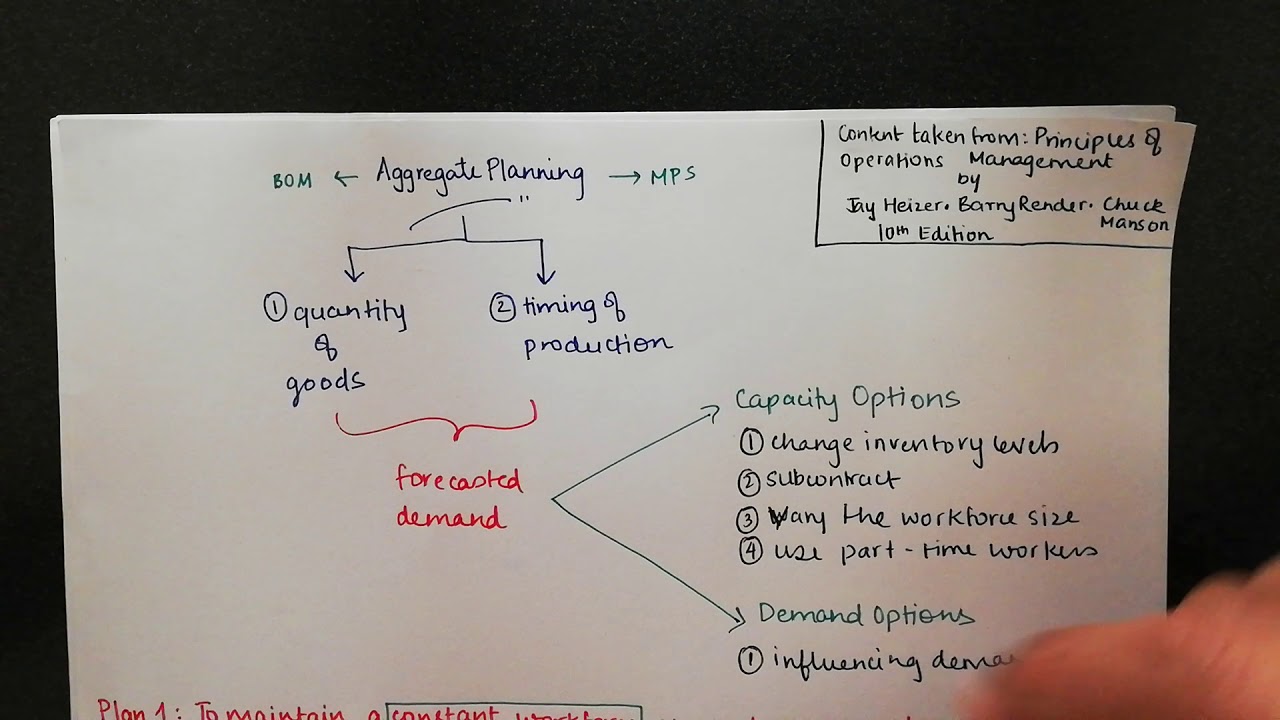

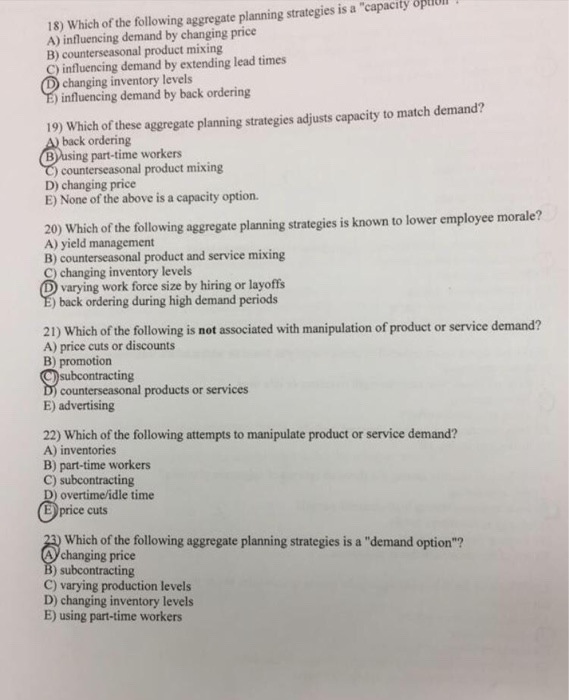

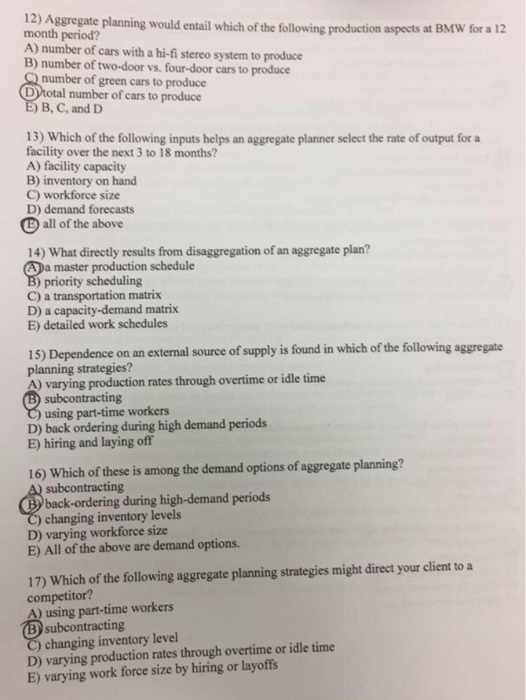

Inventory, labor level, machine capacity and warehouse space The main purpose of this model, by considering the Gulsun et al 136 different strategies that are based on the regular time production quantity is to determine overtime production quantity, Aggregate Production Planning Strategy Selection Methodology ( ) ( )Aggregate Planning (Required Inputs to the Production Planning System) Current physical capacity Planning for production External capacity Competitors' behavior Raw material availability Market demand Economic conditions Current workforce Inventory levels Activities required for prod External to firm Internal to firm 10Nov 15, 18 · Aggregate Planning strategy is mix of two strategies (Proactive – Reactive) ❖ Proactive is related to demand to match capacity ❖ Reactive related to capacity to match demand SO, Lets explain this Game 16 At The Beginning we should answer to the following questions What do we know ?

Http Sharif Edu Asamimi Site Files Course Logistics 08 Pdf

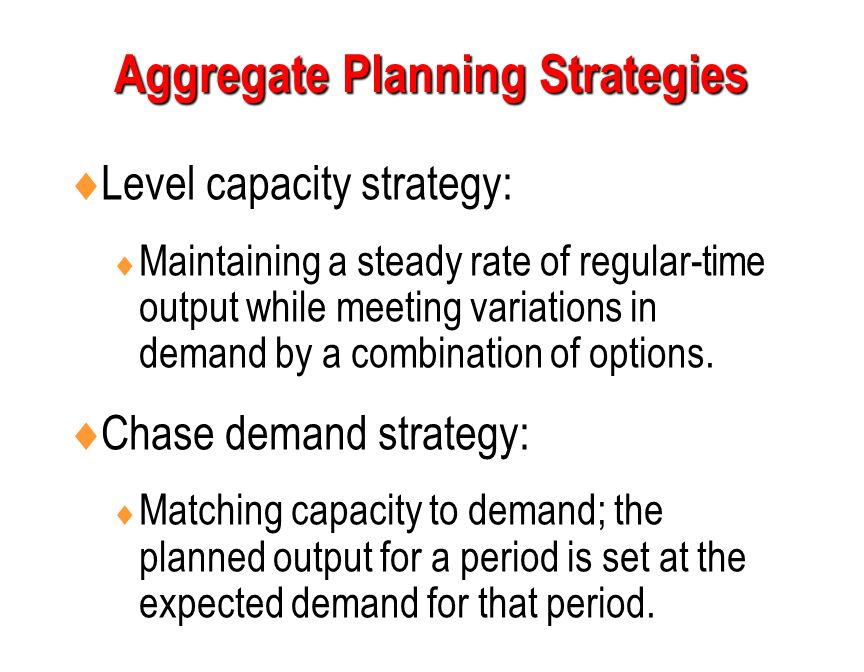

What is level strategy in aggregate planning

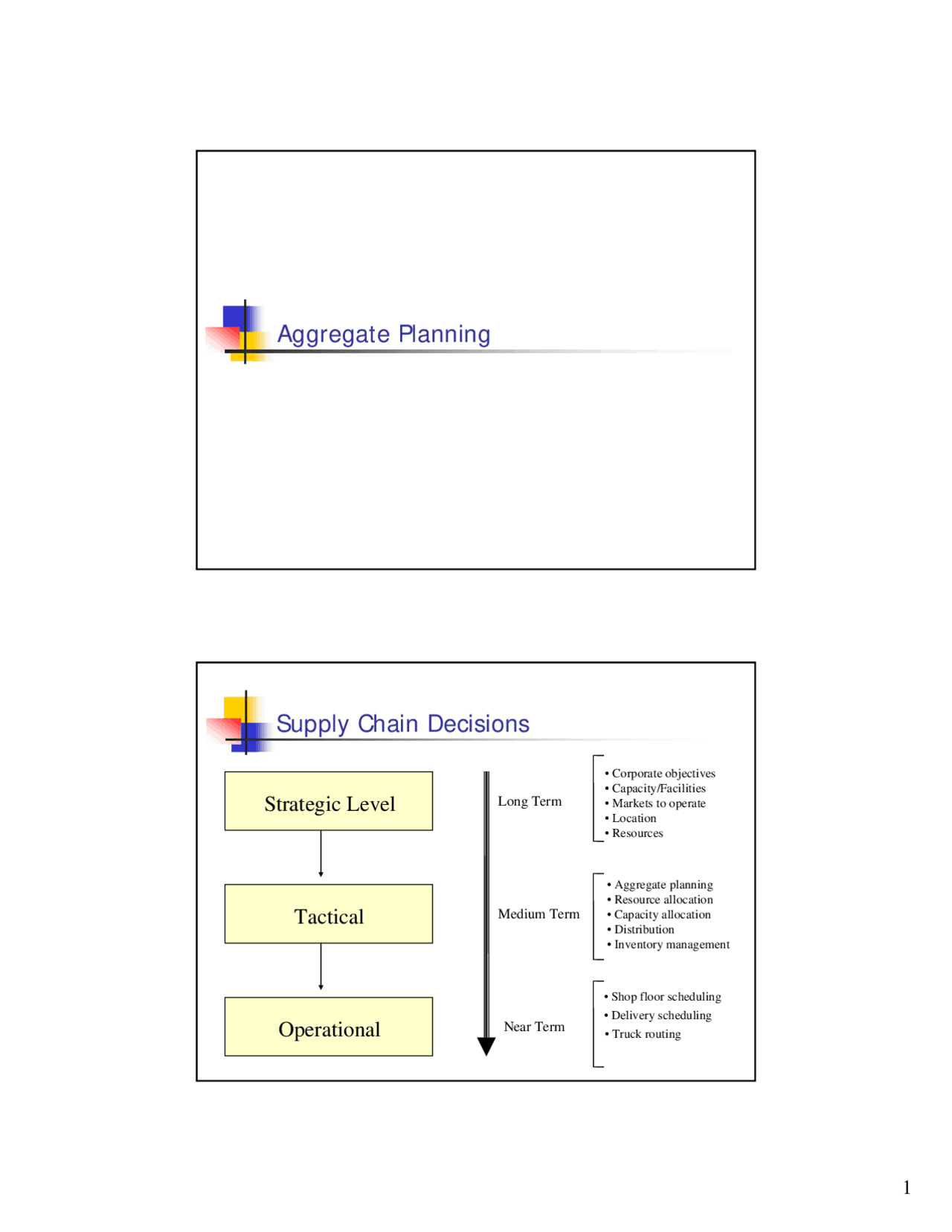

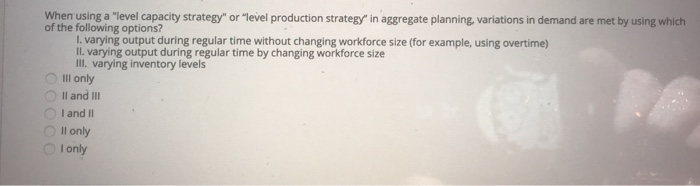

What is level strategy in aggregate planning-Aggregate planning is capacity planning for A the long range B the intermediate range C the short range D typically one to three months In order to use the "level capacity strategy," variations in demand are met by A varying output during regular time without changing employment levelsView Notes 12Aggregate_Planning from BA 3352 at University of Texas, Dallas CHAPTER 12 Aggregate Planning Planning Horizons mediumrange capacity planning, usually covering 2 to 18

Aggregate Plan And Master Production Schedule Linkage Springerlink

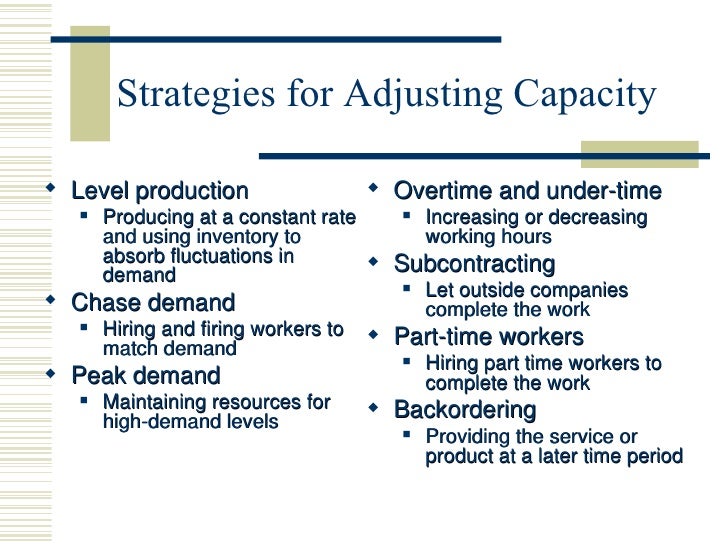

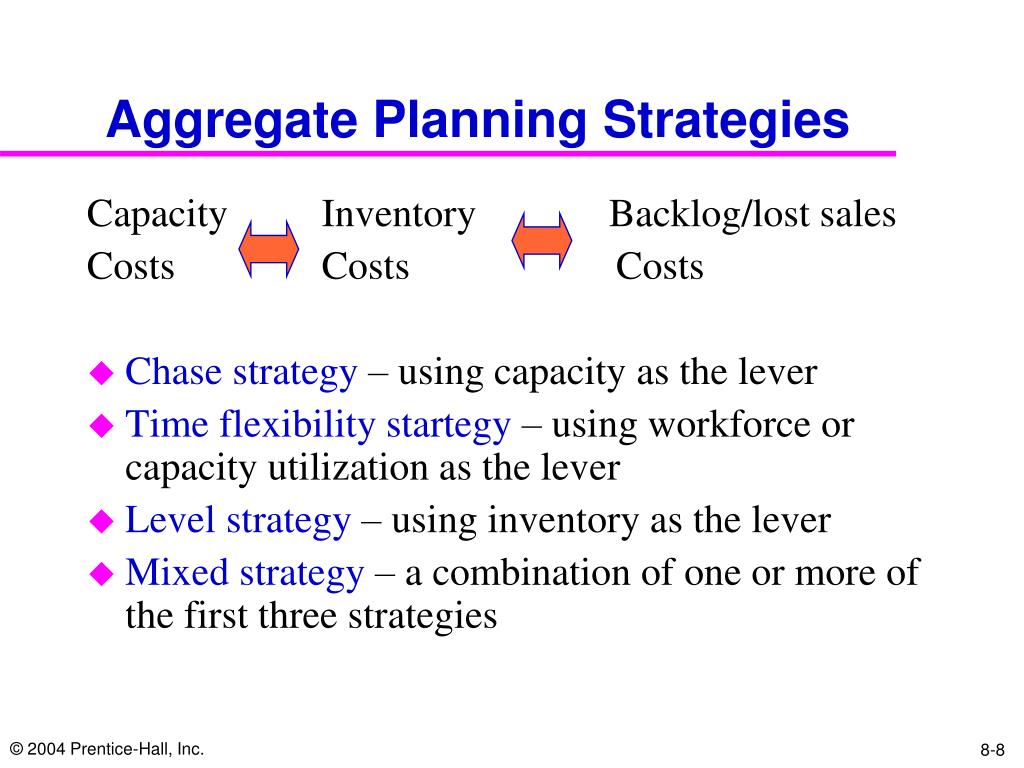

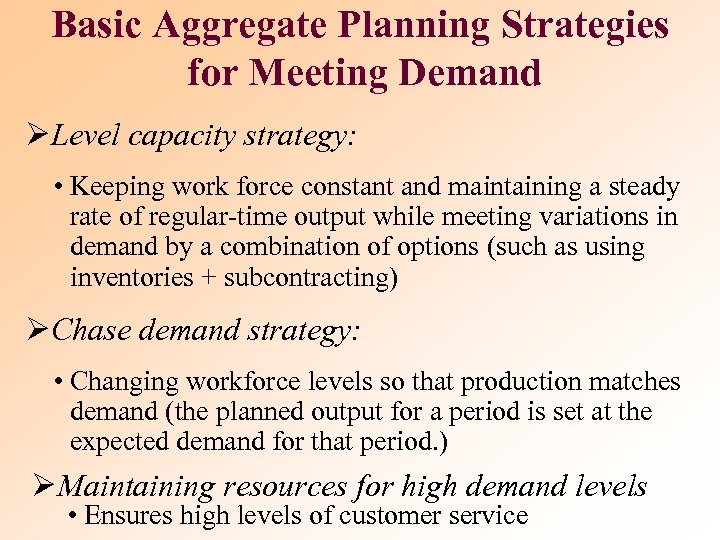

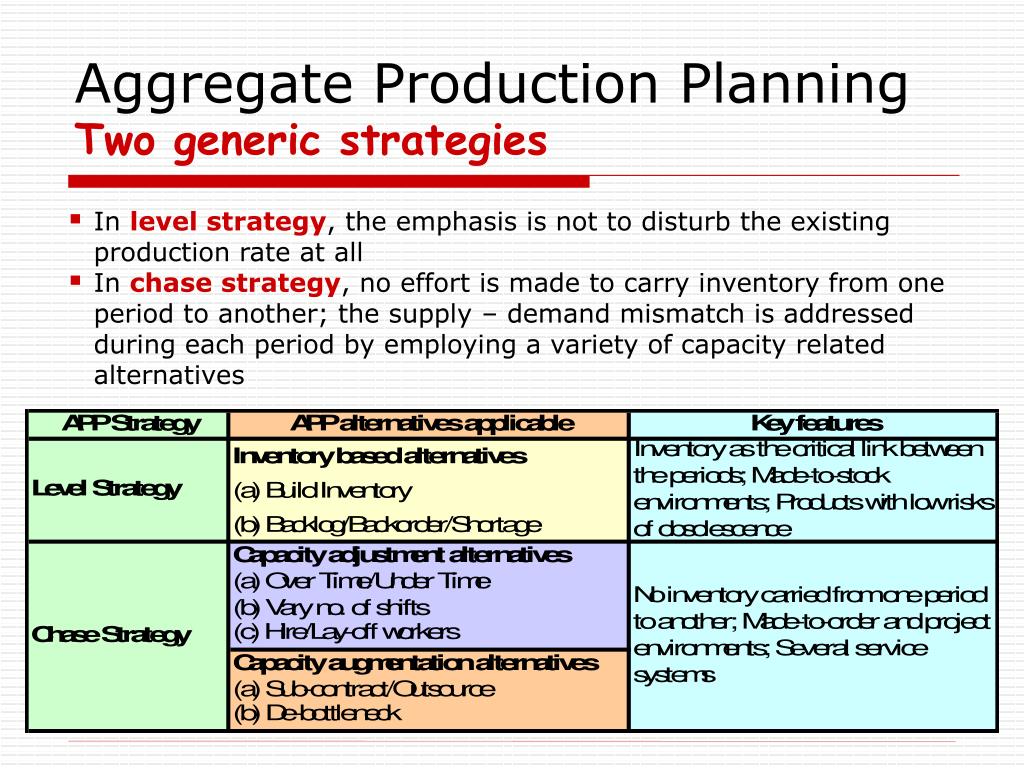

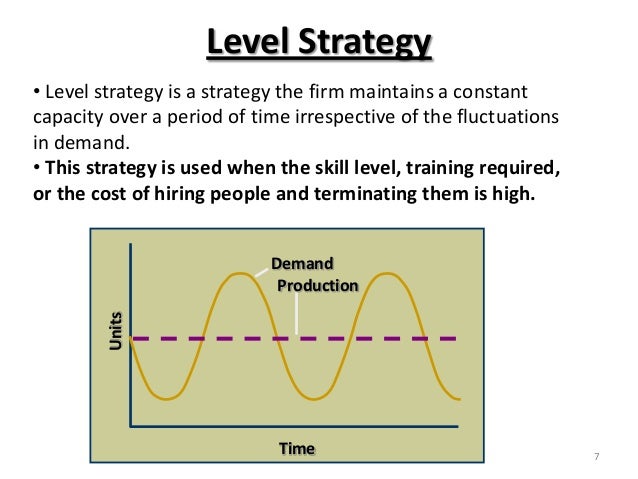

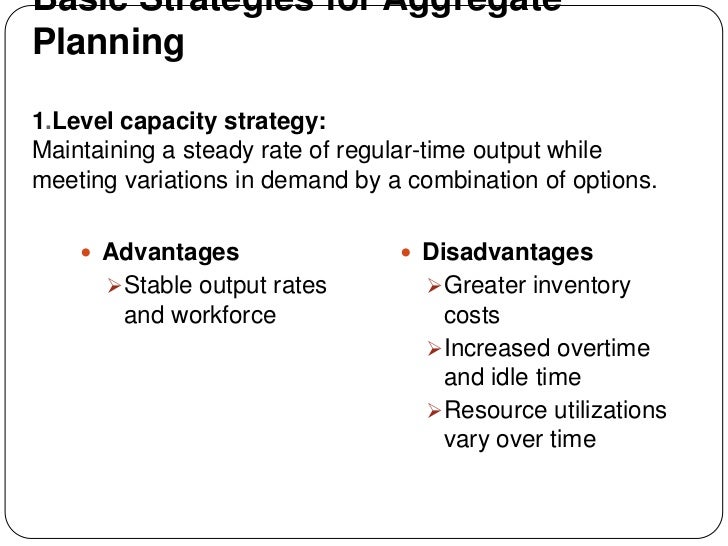

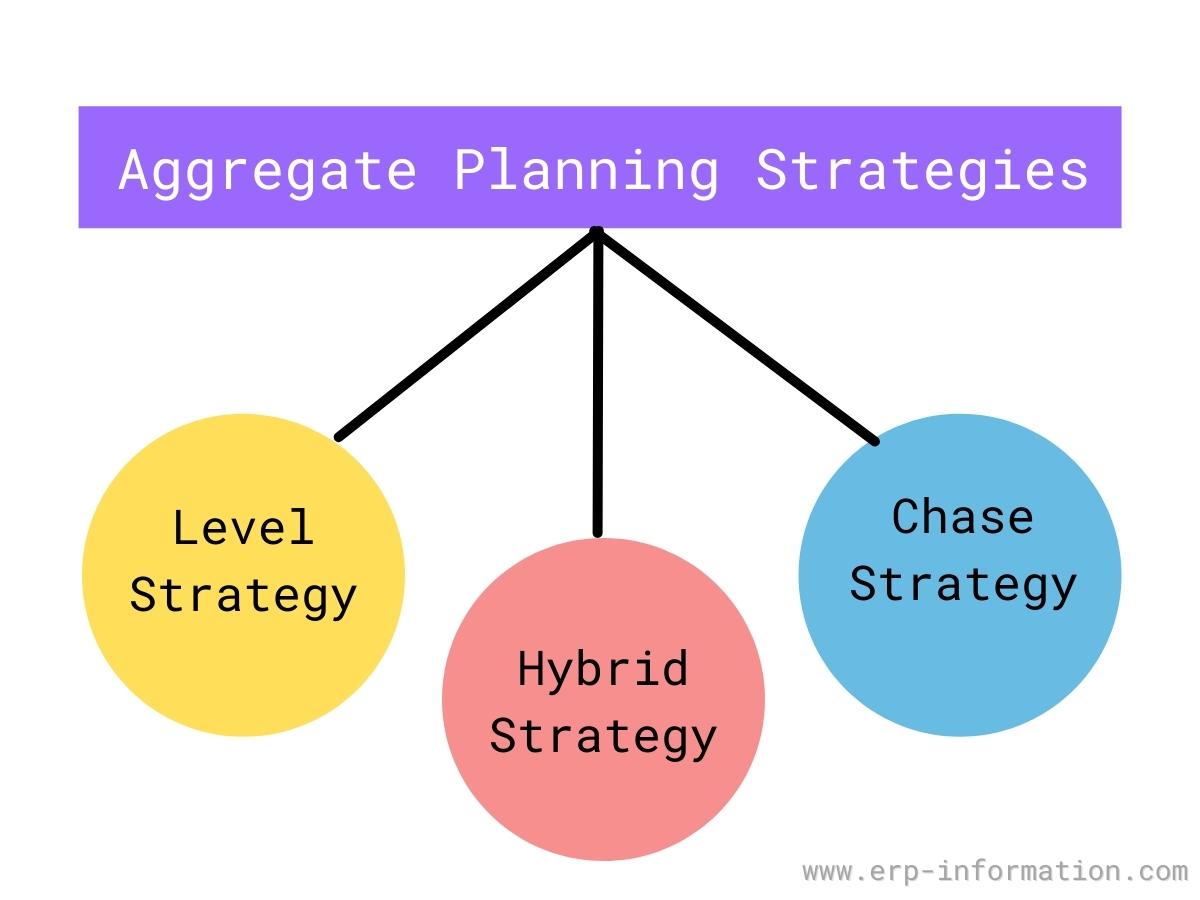

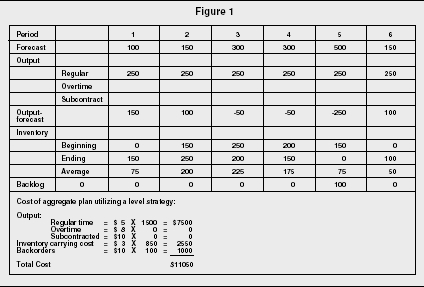

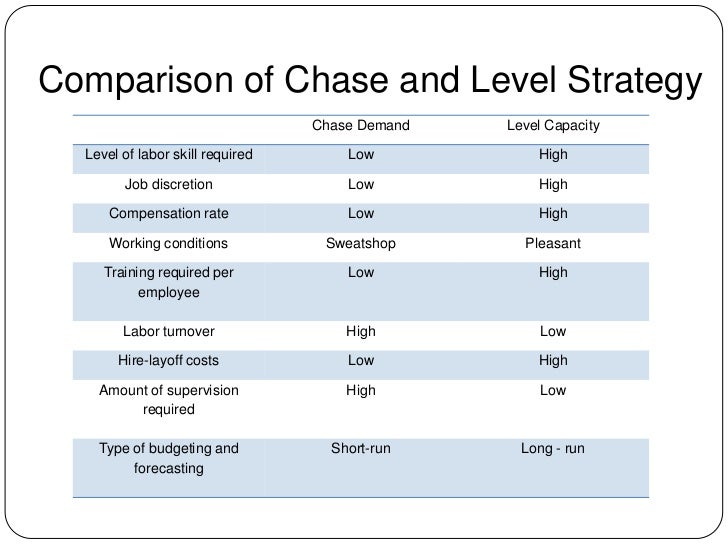

The Extremes Level Strategy Chase Strategy Production equals demand Production rate is constant Basic Aggregate Planning Strategies for Meeting Demand Level capacity strategy Keeping work force constant and maintaining a steady rate of regulartime output while meeting variations in demand by a combination of options (such as using inventoriesLevel Strategy A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level To satisfy changes in customer demand, the firm must raise or lower inventory levels in anticipation ofChapter 7 Capacity Planning and Management Learning Outcomes After reading this chapter you should be able to • Define and measure capacity and appreciate the factors that influence it • Assess the difficulties of matching capacity to demand • Evaluate and apply the different strategies for matching capacity with demand in the short,

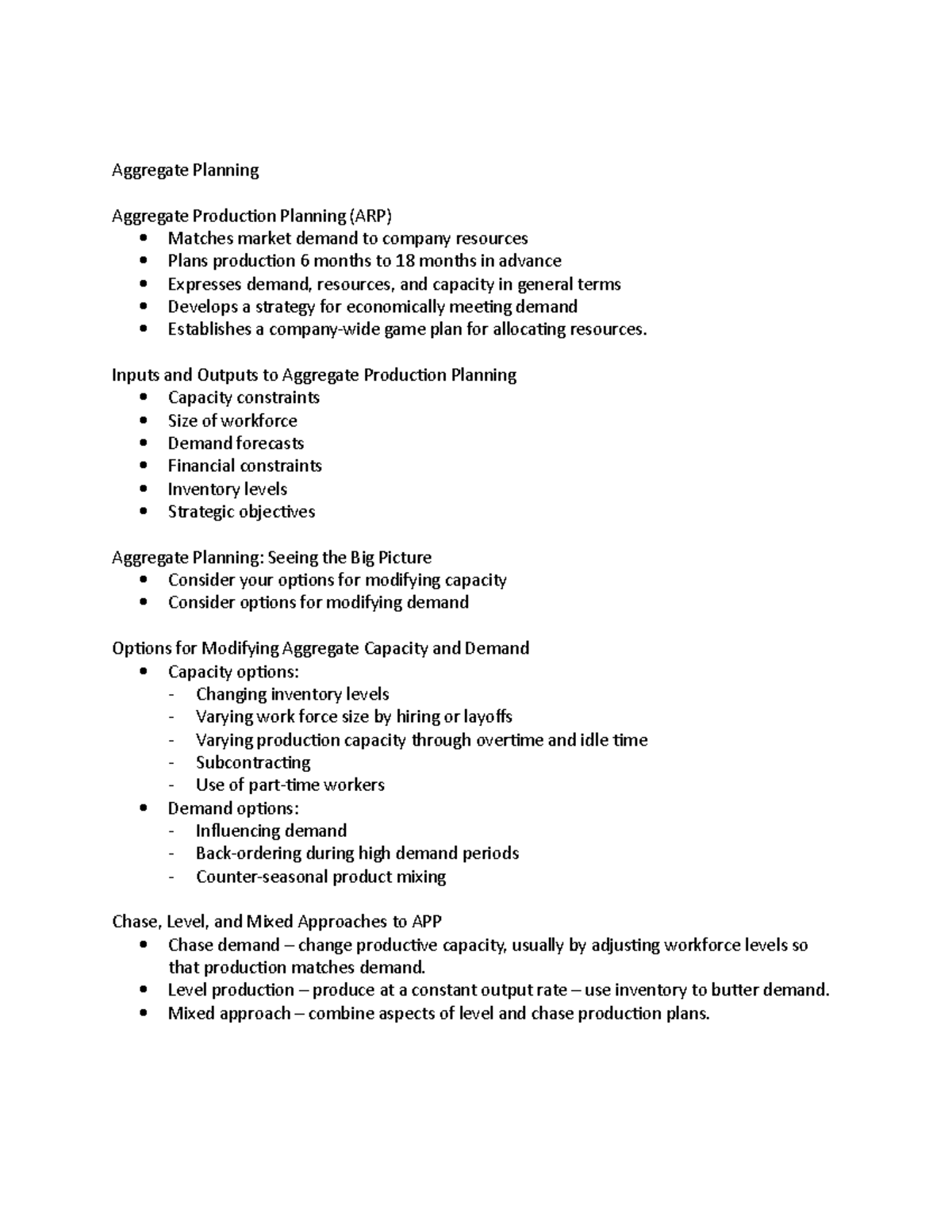

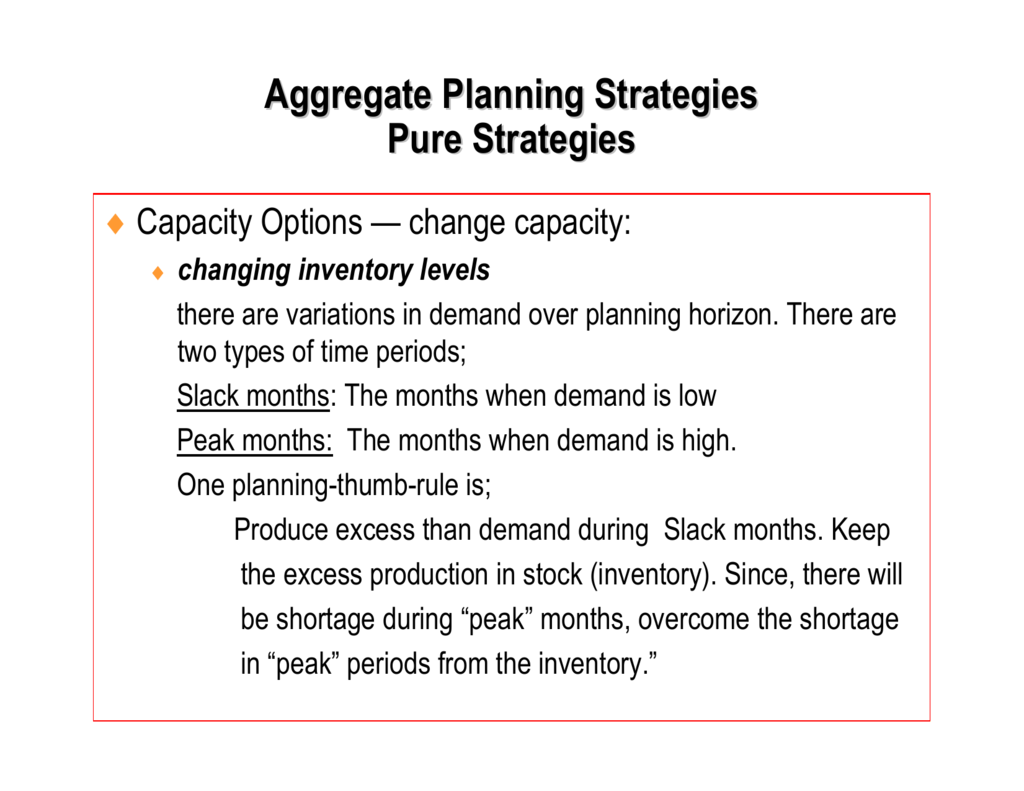

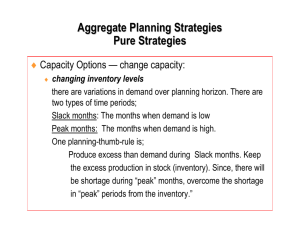

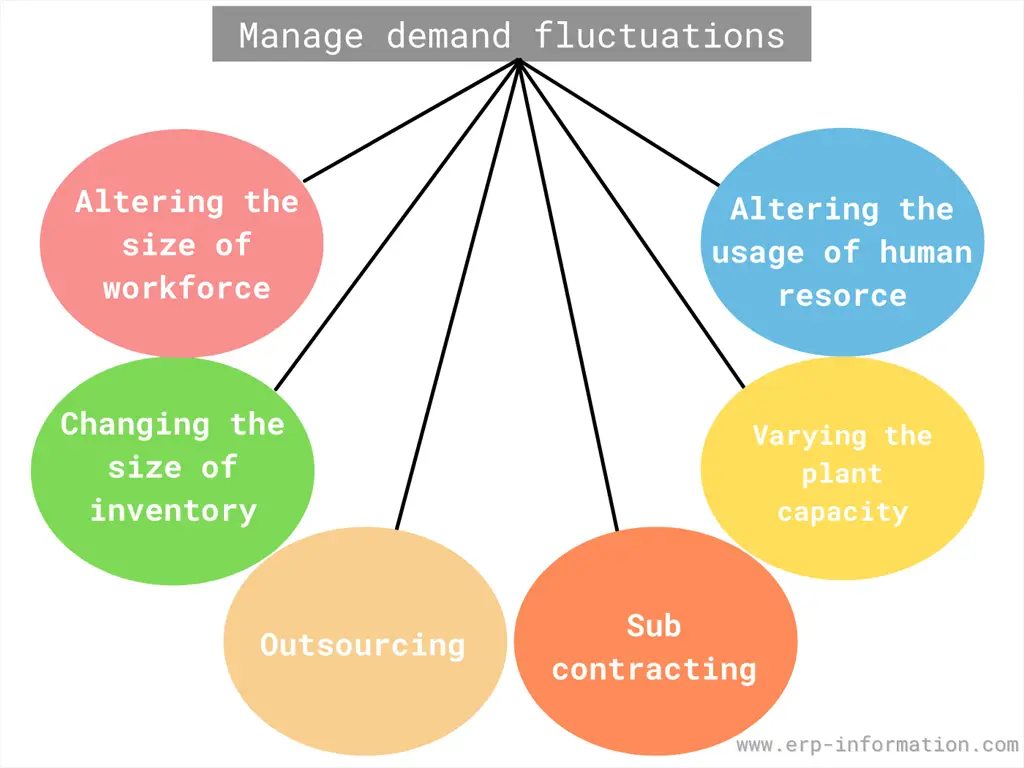

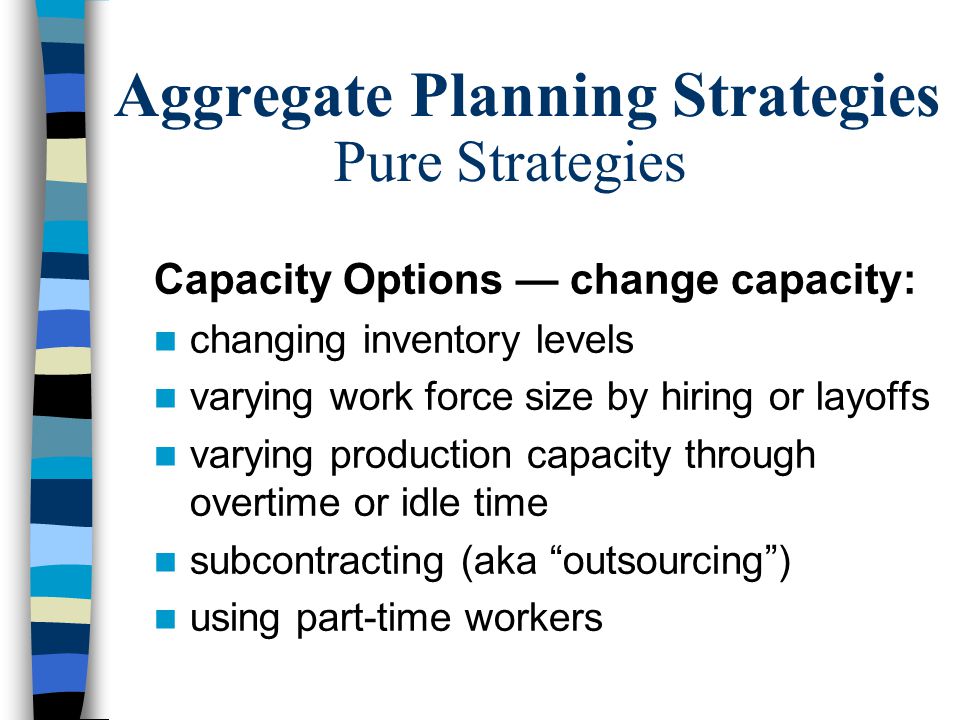

1 Aggregate Production Planning Aggregate production planning is concerned with the determination of production, inventory, and work force levels to meet °uctuating demand requirements over a planning horizon that ranges from six months to one year Typically the planning horizon incorporate the next seasonal peak in demandAggregate Planning Strategies Capacity Options Aggregate Planning Strategies 1 Use inventories to absorb changes in demand 2 Accommodate changes by varying workforce size 3 Use parttimers, overtime, or idle time to Develop a Plan Level strategyAggregate planning – Is the process by which a company determines levels of capacity, production, subcontracting, inventory, stockouts, and pricing over a specified time horizon – goal is to maximize profit Or, if demand is effectively fixed

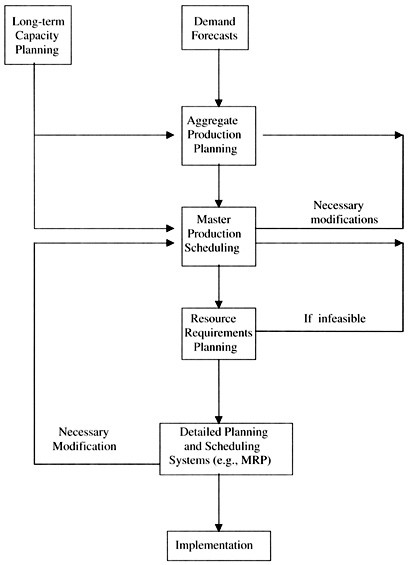

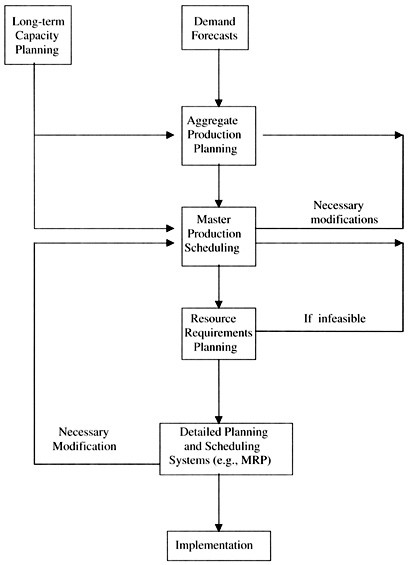

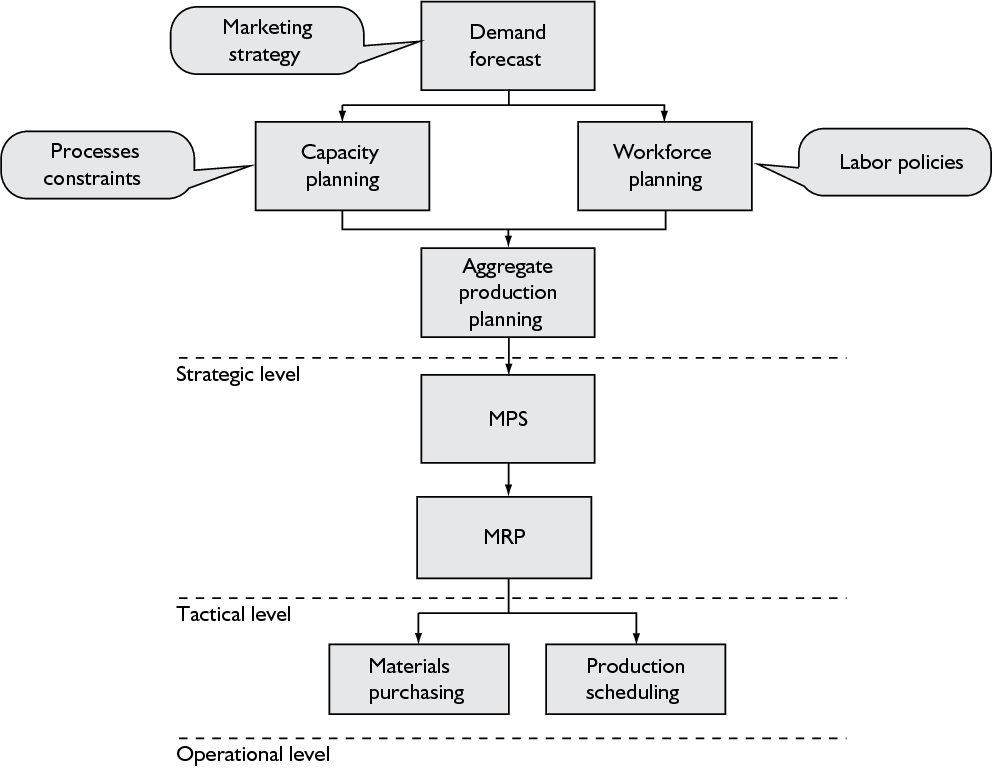

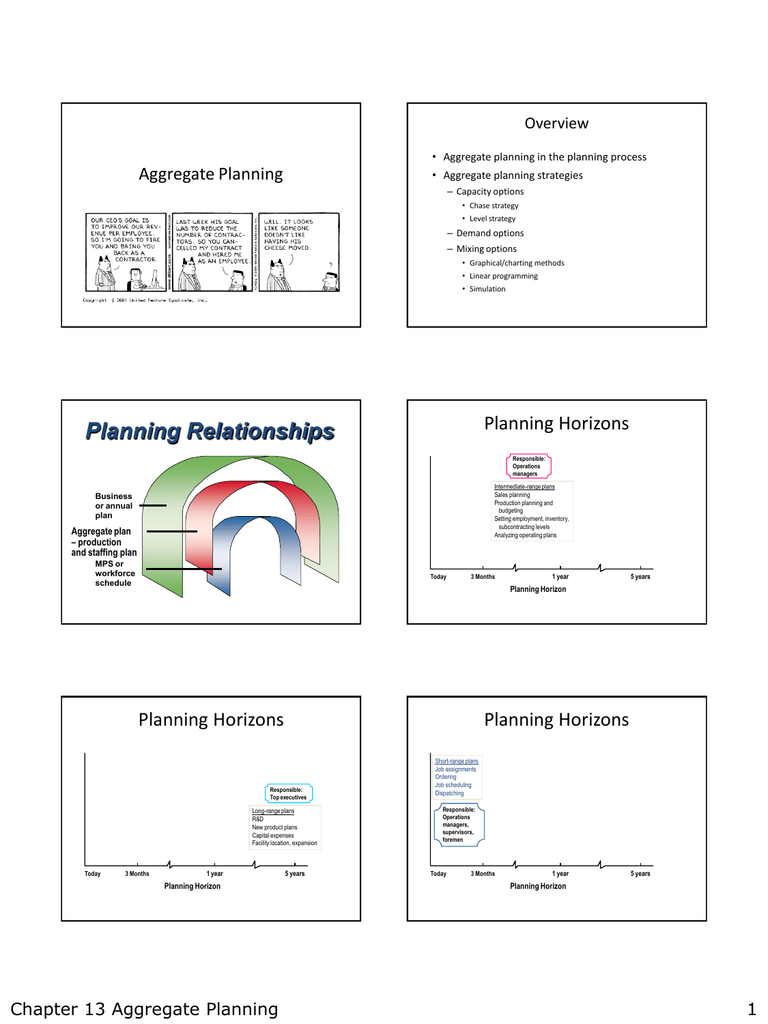

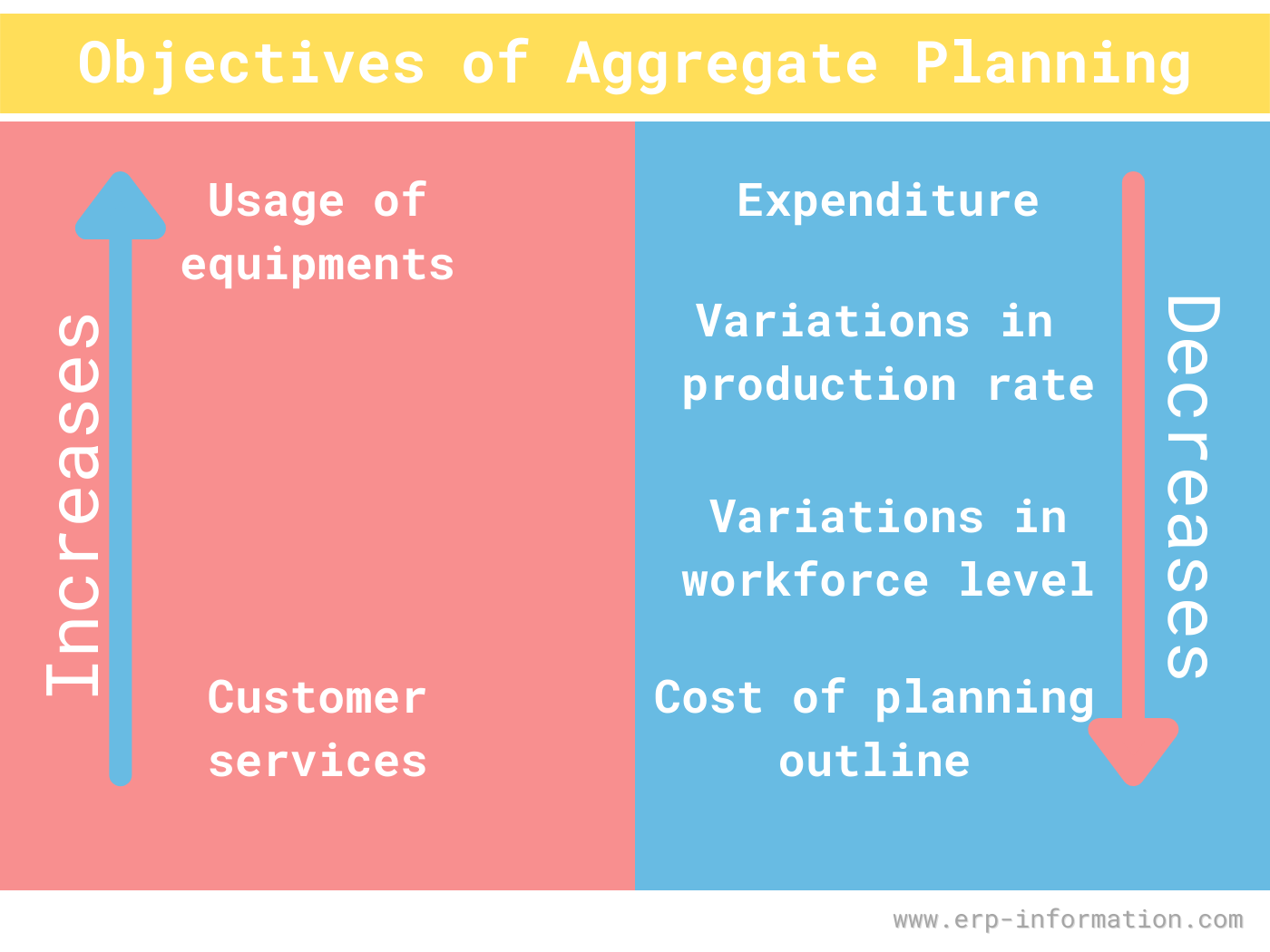

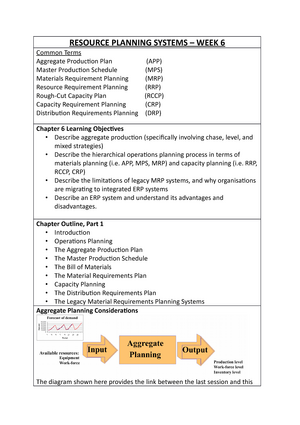

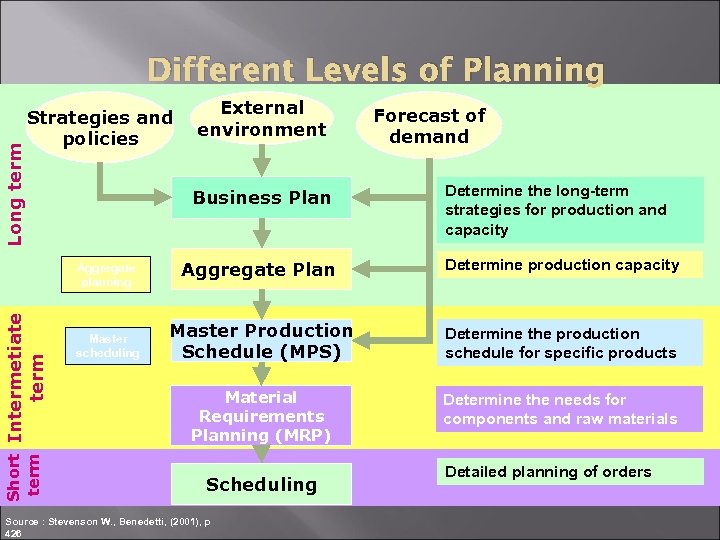

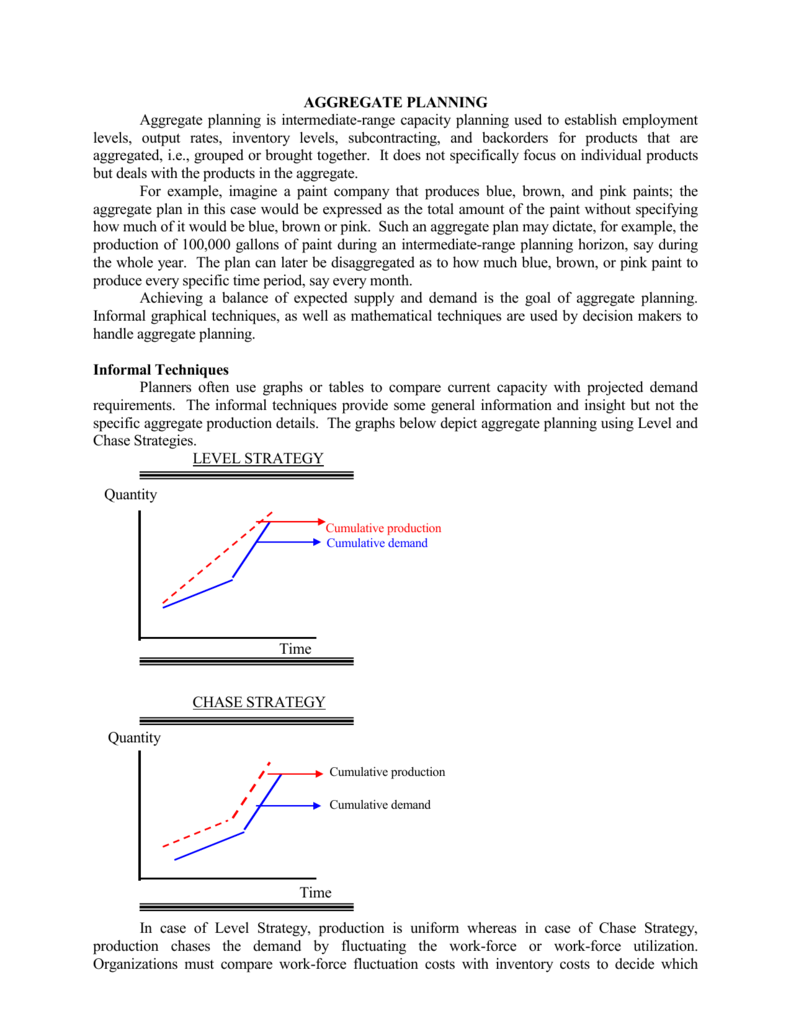

Master Scheduling Process Projected Onhand Inventory MPS Example Master Production Schedule Example Ch 13, Problem 21 Short range Intermediate range Long range Now 2 months 1 Year Business Plan Establishes operations and capacity strategies Aggregate plan Establishes operations capacity Master schedule Establishes schedules for specificKey words Capacity strategy, Level capacity, Chase capacity and Capacity utilization 1 Introduction The economic significance of capacity utilization can be expressed in the level of demand If market demand grows, the rate of utilization of capacity will increase as it is expected that output will rise Also, if demandIn simple terms, aggregate planning is an attempt to balance capacity and demand in such a way that costs are minimized The term "aggregate" is used because planning at this level includes all resources "in the aggregate;" for example, as a product line or family

1

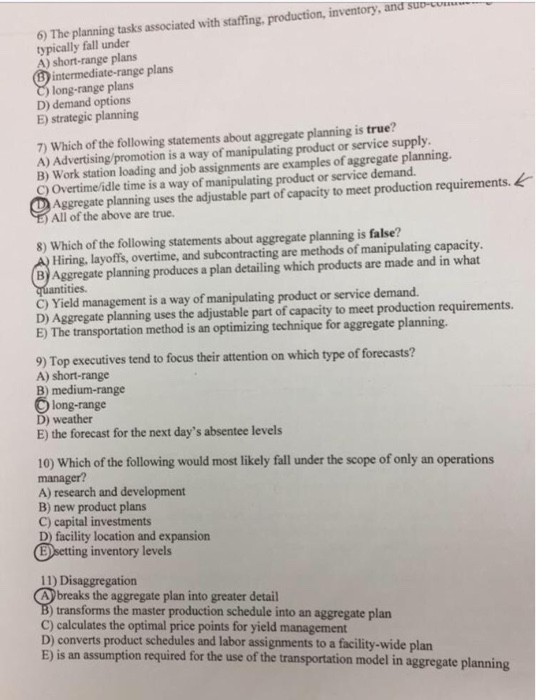

Operations Management Chapter Multiple Choice Problems Flashcards Quizlet

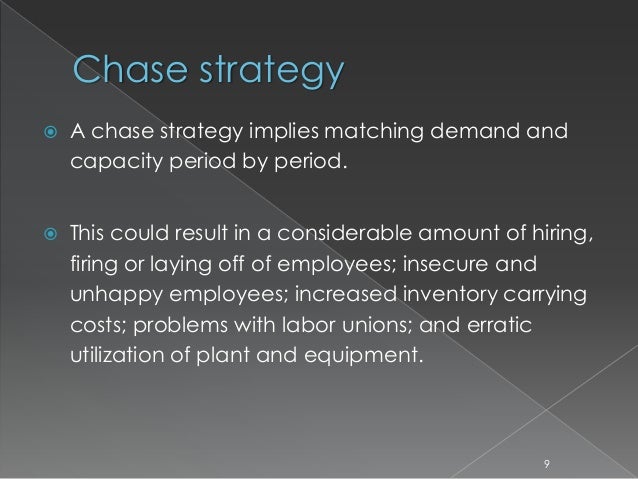

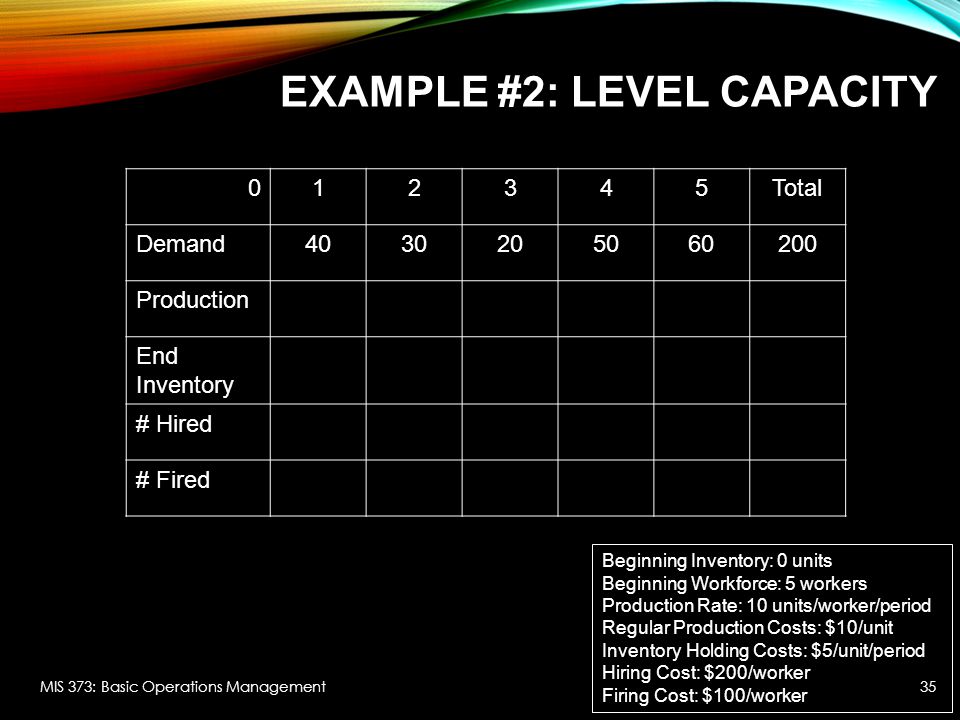

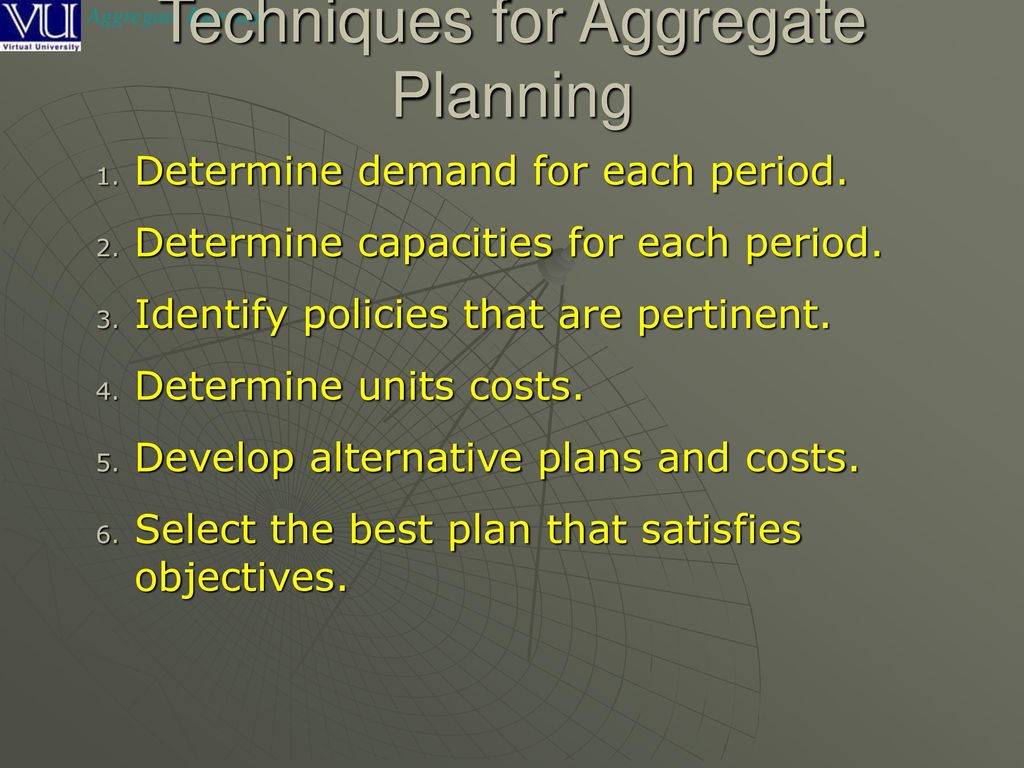

4 Select an appropriate unit of aggregate capacity 5 Determine the relevant cost structures 6 Develop an aggregate planning model Develop alternative aggregate plans and select the best plan Aggregate Planning Strategies Pure chase strategy – match demand period by period Pure level strategy – maintain a level workforce or a steadyBasic aggregate planning strategies are Level Capacity Chase Demand Demand Time period (year) Maintaining a steady rate of output while meeting variations in demand by a combination of options Level Capacity Demand Time period (one year) Production Production Cumulative production Cumulative demand Cumulative output/demand InterestingMar 04, 21 · Aggregate Planning level capacity and chase demand strategy Aggregate planning for widget maker chase plan with steady level vs a chase strategy Aggregate demand requirement, chase and level strategy Aggregate production plan Aggregate Planning and Scheduling Aggregate production planning Chaseproduction and level production

D Aggregate Planning Uses The Adjustable Part Of Capacity To Meet Production Course Hero

Http Sharif Edu Asamimi Site Files Course Logistics 08 Pdf

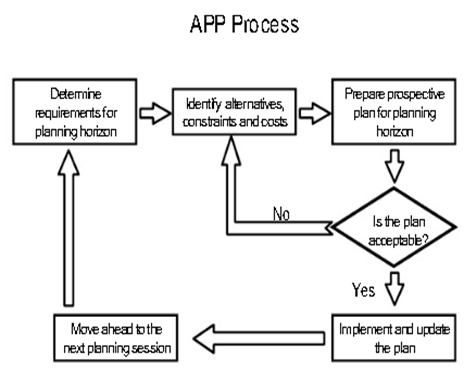

I Varying Output During Regular Time Without Changing Workforce Size (for Example, Using Overtime) II Varying Output During Regular Time By Changing Workforce Size IIIDeveloping the Aggregate Plan Step 1 Choose strategy level, chase, or Hybrid Step 2 Determine the aggregate production rate Step 3 Calculate the size of the workforce • Aggregate planning, MPS, and roughcut capacity affection functional areasAggregate planning is a marketing activity that does an aggregate plan for the production process, in advance of 6 to 18 months, to give an idea to management as to what quantity of materials and other resources are to be procured and when, so that the total cost of operations of the organization is kept to the minimum over that period The quantity of outsourcing,

Capacity Planning An Industry Guide Plex Demandcaster

1

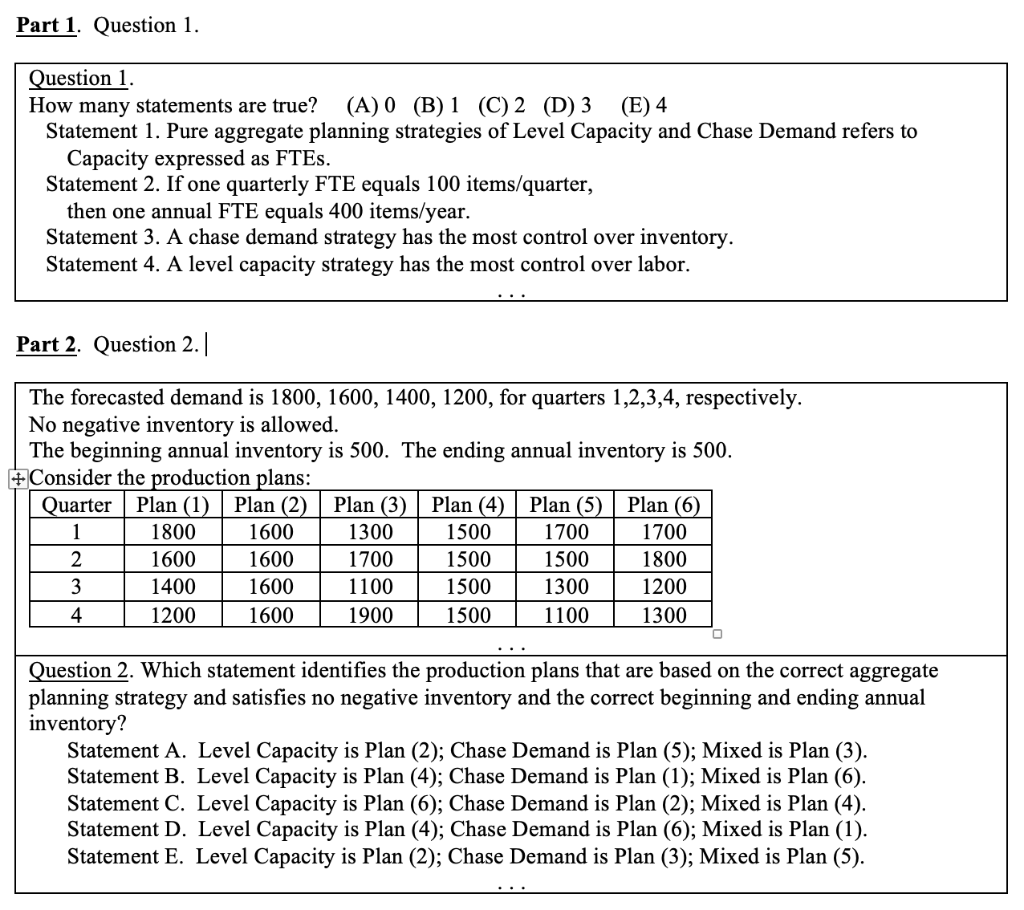

The primary difference among the three strategies is the lever, When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demandIntermediate range capacity planning that typically covers a time horizon of 2 to 18 months "Pure" aggregate planning strategies proactive alter demand to match capacity the planned output for a period is set at the expected demand for that period level capacity strategy maintaining a steady rate of regulartime output whileJun 27, 21 · With a beginning annual inventory of 600 and an ending annual inventory of 600, which set of values are correct for a Level Capacity aggregate planning strategy within Solution and Analysis Tables?

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Aggregate Planning Lecture Slides Isye 3104 Docsity

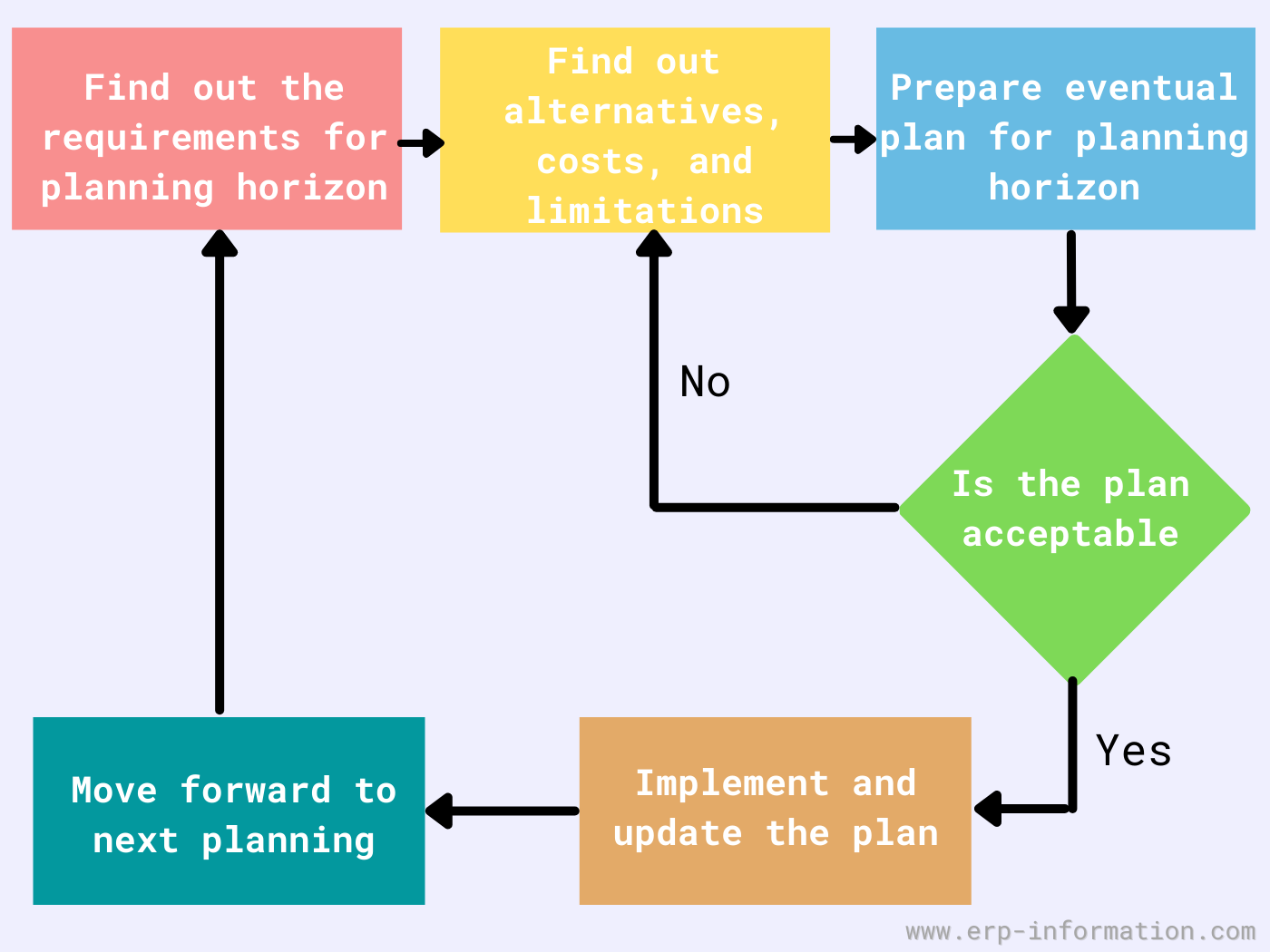

Feb 04, 15 · Aggregate planning becomes successful when both aggregate demand and aggregate capacity are equal When there is an imbalance between them, then the organization has to decide whether to add or reduce capacity to attain demand or add or reduce demand to attain capacityJul 19, 19 · Cost Advantages of Aggregate Planning Aggregate planning is concerned with determining the quantity and the schedule of production for the immediate future Aggregate plans are intermediaterange plans that are valid for three to 18 months The main objective of aggregate plans is to lower costs and to use capacity most efficientlyCapacity Planning Capacity planning is a longterm strategic decision that establishes a firm's overall level of resources It extends over a time horizon long enough to obtain those resourcesusually a year or more for building new facilities or acquiring new businesses Capacity

Doc Chapter Stuti Agrawal Academia Edu

M Which Of The Following Is The Term Used For Medium Chegg Com

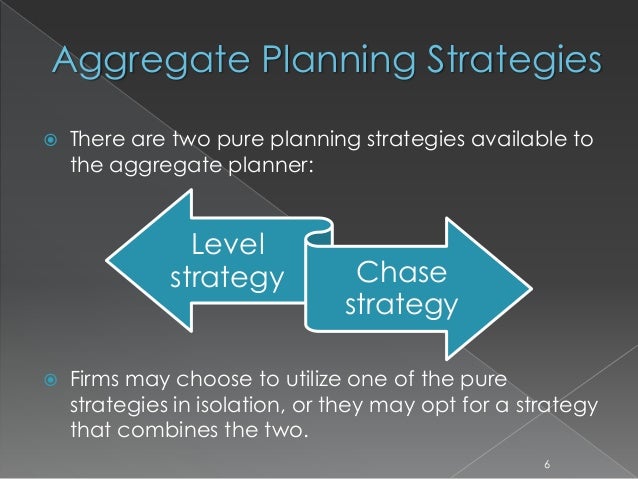

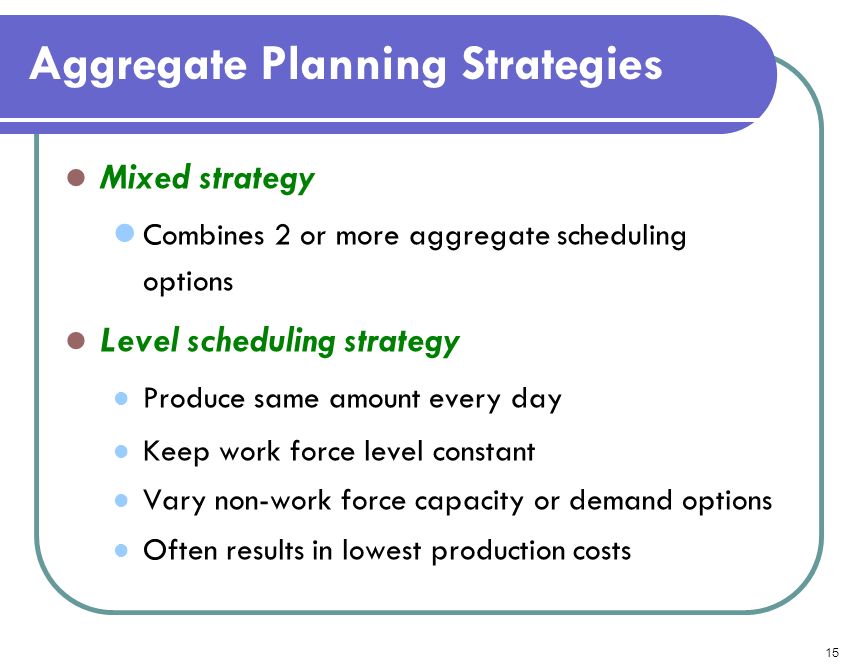

Jan 21, · The aggregate planning that we are going to carry out will among other things attempt to match the level of bike supply to demand It is going to determine the required quantities and the timing of inputs as well as outputs There will also be making decisions on production, inventory, staffing and backorder levelsThere are two pure planning strategies available to the aggregate planner a level strategy and a chase strategy Firms may choose to utilize one of the pure strategies in isolation, or they may opt for a strategy that combines the two LEVEL STRATEGY A level strategy seeks to produce an aggregate plan that maintains a steady production rateJan 14, · What strategies are used for aggregate planning and what are the main differences between these strategies?

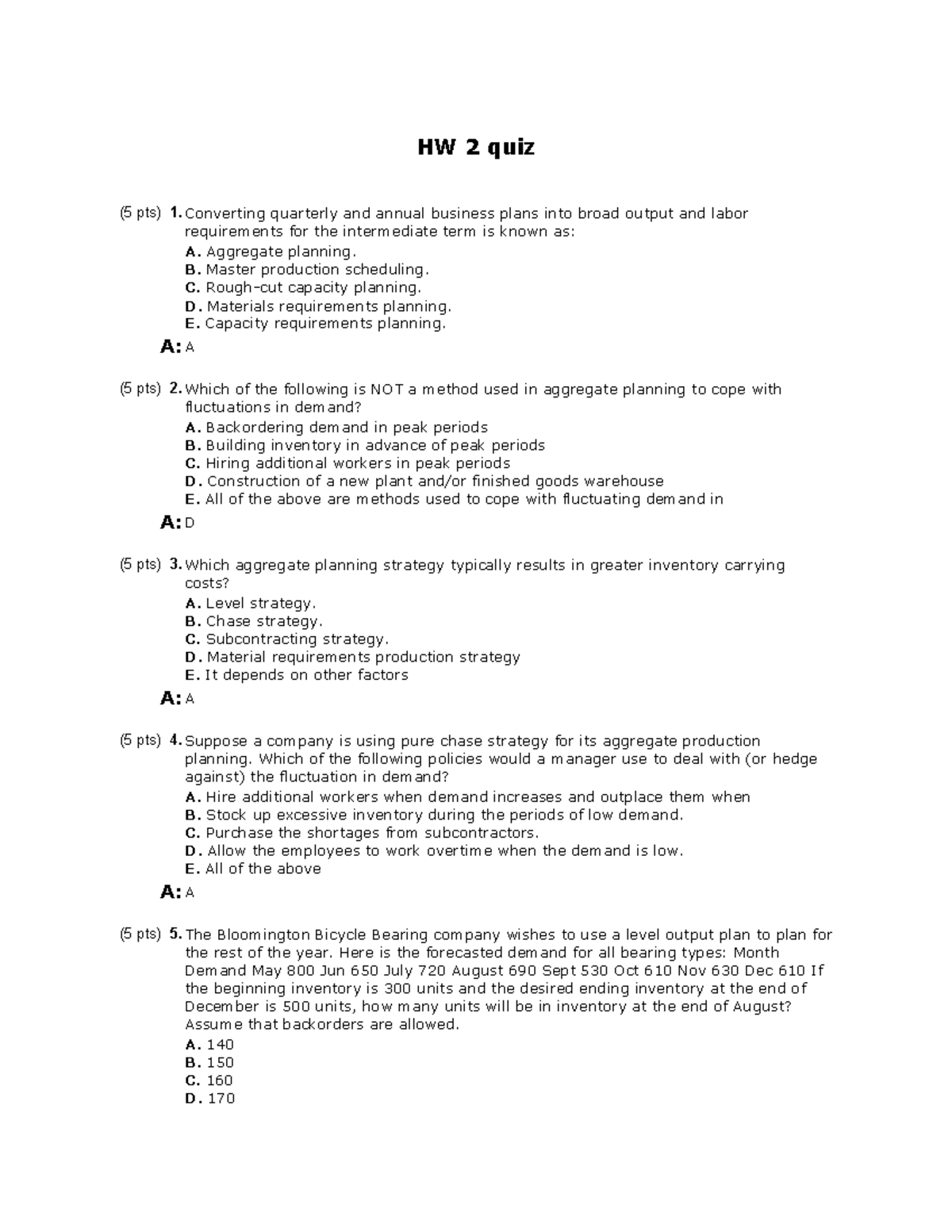

Hw2 Quiz With Answers Hw Quiz Pts Converting Quarterly And Annual Business Plans Into Broad Output And Labor Requirements For The Intermediate Term Is Known As Studocu

Http Site Iugaza Edu Ps Aschokry Files 11 09 Om Chap 13 Aggr Plan2 Pdf

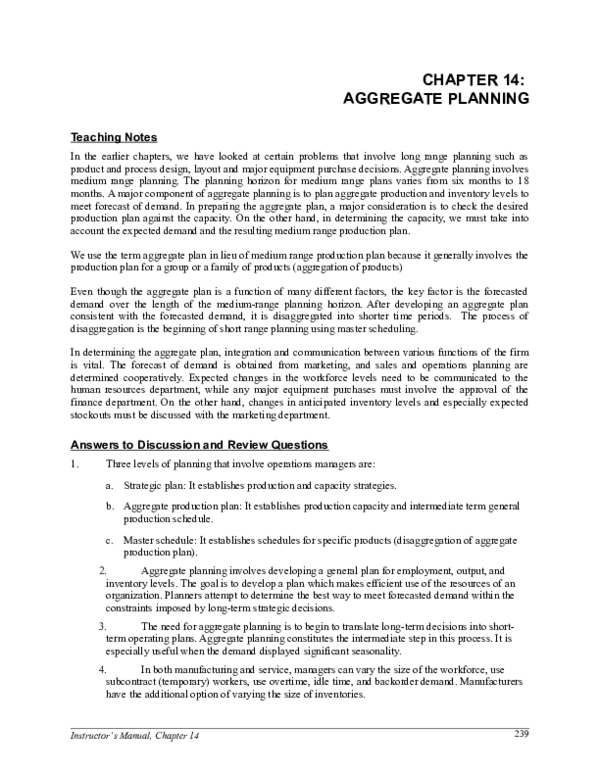

Based on Chapter 13 of Heizer and RenderApr 21, 11 · The reactive aggregate planning strategy creates changes in the capacity to match with the changing demand Here are options widely used when developing the reactive aggregate planning strategy Resource Management Companies change resource management policies by hiring employees with required skills and lay off those without the right skillsQuestion When Using A "level Capacity Strategy" Or "level Production Strategy" In Aggregate Planning, Variations In Demand Are Met By Using Which Of The Following Options?

Strategies For Developing Aggregate Plans Assignment Help Aggregate Planning Process

Operations Management Aggregate Planning Chapter 13 Transparency Masters

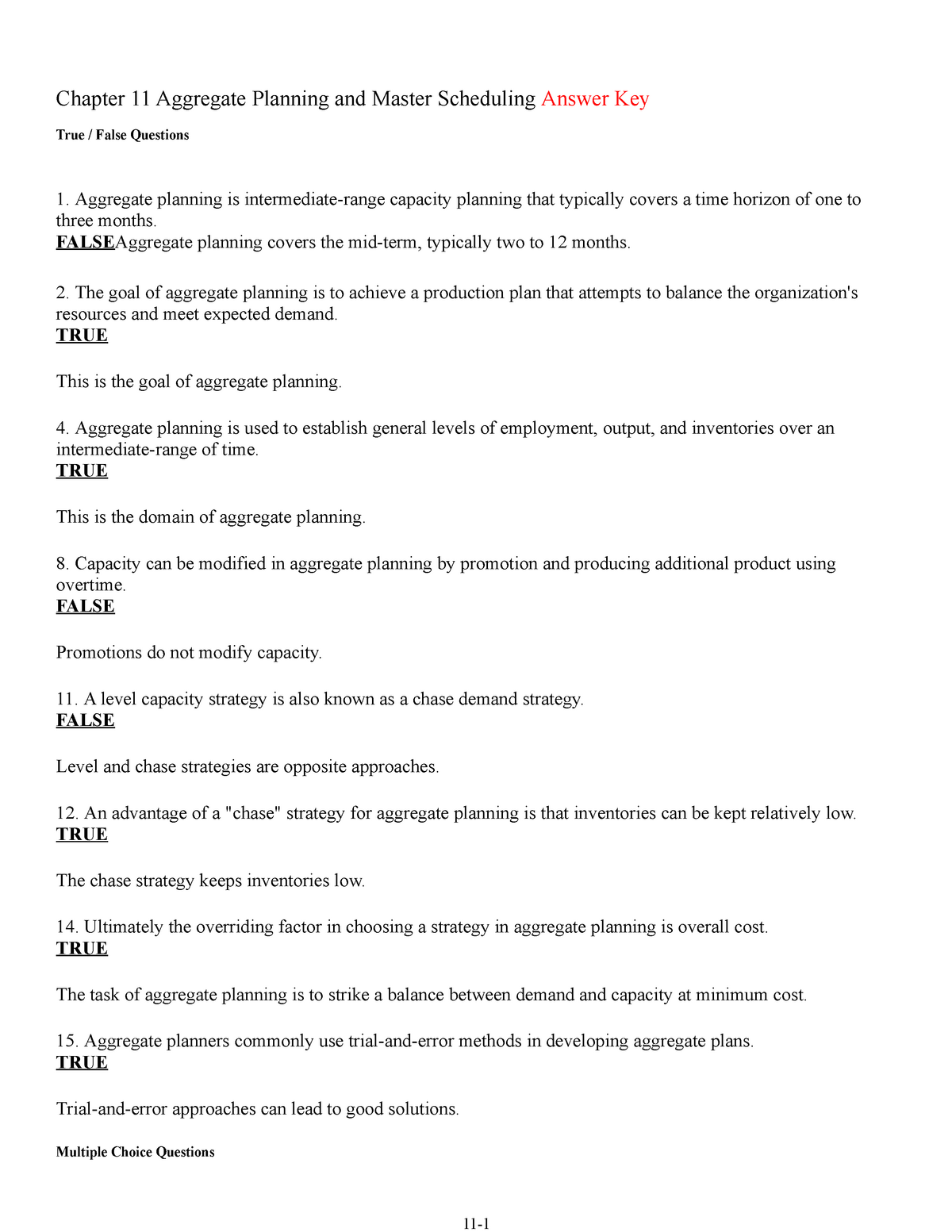

Jan 06, · Aggregate planning is mediumterm capacity planning that typically covers a period of two to 18 months Like capacity planning, aggregate planning considers the resources needed for production such as equipment, production space, time and labor11) Aggregate planning also can serve as an important input to other strategic decisions, for example, management may decide to add capacity when aggregate planning alternatives for temporarily increasing capacity, such as working overtime and subcontracting, are too costly In doing the business, when aMar 10, · The level strategy is considered a traditional aggregate planning method that maintains a steady production rate as well as the level of the workforce by continuing consistent human resources and production in the organization It is best suited where the inventory carrying costs are not high and are adopted by mainly manufacturing companies

Aggregate Planning Definition Importance Strategies Management And Advantages

Aggregate Planning Lecture Notes 10 14 Studocu

Feb 22, · LEVEL STRATEGY A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment levelStrategic Network Planning Master Planning Distribution Planning Transport Planning Production Aggregate Planning a Level Work Force Plan `backorders allowed Aggregate Planning Available capacity 50 50 10 12 14 16 0 350 150 50 75 75 0 300 300Jul 24, · Aggregate planning is the practice of balancing a business's capacity and demand over a period of time — usually a year — to maximize profits

Pdf Aggregate Production Planning For A Pump Manufacturing Company Level Strategy

Everything About Capacity Planning Strategies Its Benefits

In other words, a level strategy is an aggregate plan in which production is uniform from period to period Firms like Toyota and Nissan keep production at uniform levels and may (1) let the finished goods inventory go up or down to buffer the difference between demand and production, or (2) find alternative work for employeesAGGREGATE PLANNING Deciding on the level of capacity (eg, physical capacity or labor) of a firm and on how to readjust that capacity to respond to changing demand conditions A way of translating demand forecasts into a blueprint for staffing/capacity and production levels for the firm over a predetermined planning period AggregationJul 01, 21 · An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality

Csbapp Uncw Edu Janickit Ops370 Modules Module10 Pdf

Advantages Of Aggregate Planning

Aggregate planning examples San Aziz Example 1 A large distribution center must develop a staffing plan that minimizes the total cost using parttime workers Use chase and level strategyPlanning Horizon Aggregate planning Intermediaterange capacity planning, usually covering 2 to 12 monthsThe present study proposes a novel decision model to aggregate production planning (APP) decision making problem based on mixed chase and level strategy under uncertainty where the market demand

Aggregate Planning Strategies Methods And Examples Harappa Education

Larry Smith The Manager Of Cases For You Wants To Use Aggregate Planning For The Company S Line Of Rugged Carryon Suitcases Below Is The Company S Course Hero

Jul 04, 13 · Level strategy Chase strategy 6 7 Level strategy A level strategy seeks to produce an aggregate plan that maintains a steady production rate and a steady employment level In order to satisfy changes in customer demand, the firm must raise or lower inventory levels in anticipation of increased or decreased levels of forecast demand 7Aggregate planning Aggregate planning involves planning the best quantity to produce in the intermediaterange horizon (3 months to one year) and planning the lowest cost method of providing the adjustable capacity to accommodate the production requirements For Example At the end of the aggregate production planning exercise , a garments manufacturer may arrive at the following plan

Aggregate Plan And Master Production Schedule Linkage Springerlink

Aggregate Planning Strategies Chase Strategy Capacity Strategy Level Strategy a 5th Sem Cu Youtube

Aggregate Planning

Aggregate Planning

Aggregate Planning Strategies Pure Strategies

Aggregate Capacity Planning Pdf Free Download

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Aggregate Planning And Learning Curves Chapter Outline 1

Pdf Evaluating The Performance Of Aggregate Production Planning Strategies Under Uncertainty In Soft Drink Industry

Aggregate Planning For A Large Food Manufacturer With High Seasonal Demand Semantic Scholar

Http Www1 Pu Edu Tw Ylai Erp Dom 1042 Ppts S16 1042 Erp Dom Ap S16 Pdf

Sales And Operations Planning Aggregate Planning Production Planning

Aggregate Planning

Ppt Chapter 8 Aggregate Planning In The Supply Chain Powerpoint Presentation Id

Aggregate Planning Planning Horizon Aggregate Planning Intermediate Range

Ppt Aggregate Production Planning Powerpoint Presentation Free Download Id

1

Models Of Aggregate Planning

Chapter 13 Aggregate Planning

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Master Production Schedule An Overview Sciencedirect Topics

Aggregate Planning Report

Aggregate Production Planning Operations Management Homework And Assignment Help

Capacity Planning Meaning Classification And Its Goals

Solved When Using A Level Capacity Strategy Or Level P Chegg Com

Aggregate Planning Inventory Labour Economics

Solved Give Me Some Ideas Aggregate Planning In A Supply Chain Is Course Hero

Aggregate Planning

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Solved Part Ii Assume The Company Wants To Use A Level Ca Chegg Com

Sustainability In Supply Chain Management Aggregate Planning From Sustainability Perspective

Aggregate Production Planning Aggregate Planning Process Aggregate Production Planning Strategies

Planning Relationships Planning Horizons Aggregate Planning

Aggregate Planning

M Dc Operations Strategy

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Part 1 Question 1 Question 1 How Many Statements Chegg Com

Chap011 Aggregate Chapter 11 Aggregate Planning And Master Scheduling With Answers Studocu

Aggregate Planning 101 What You Need To Know Brendan Jones

Aggregate Planning Ppt Download

Master Production Schedule

Aggregate Planning Chapter 11 Aggregate Planning Aggregate Planning

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Aggregate Planning Definition Importance Strategies Management And Advantages

Http Www1 Pu Edu Tw Ylai Erp Dom 1042 Ppts S16 1042 Erp Dom Ap S16 Pdf

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

Sihombing15 Files Wordpress Com 08 08 Ch 7 Aggregate Capacity Planning Pdf

Myclass Dau Edu cswebdav Xid 4 2

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Aggregate Planning Strategies Of Scm Inventory Demand

Master Production Schedule An Overview Sciencedirect Topics

Case Study Red Tomato Aggregate Plan Part 1 By Fpt Technology Official

Capacity Planning An Industry Guide Plex Demandcaster

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

Methods For Aggregate Planning Inventory Labour Economics

Slides Show

Aggregate Production Planning Aggregate Planning Process Aggregate Production Planning Strategies

Aggregate Capacity Planning Pdf Free Download

Week 6 Resource Planning System Studocu

12 1 Aggregate Planning Operations Management William J

Chapter 8 Aggregate Planning In The Supply Chain

Pdf Analysis Of Aggregate Planning For Development Strategy Case Study Of Gasoline Distribution Company In Indonesia Semantic Scholar

Production Planning And Control The Objectives Of

Pdf Evaluating The Performance Of Aggregate Production Planning Strategies Under Uncertainty In Soft Drink Industry

Aggregate Planning Mps Capacity Planning Strategic Management Inventory

Aggregate Planning Strategies Of Scm Inventory Demand

Which Of These Aggerate Planning Strategies Is A Capacity Option Nadex Cfpb Complaint

M Which Of The Following Is The Term Used For Medium Chegg Com

Aggregate Planning Report

M Which Of The Following Is The Term Used For Medium Chegg Com

1

Production Planning Control Chapter 2 Aggregate Planning Master Production Scheduling Chapter2 1 Pdf Free Download

Aggregate Planning Definition Importance Strategies Management And Advantages

Operations Management Aggregate Planning Chapter Ppt Video Online Download

Operations Management Focusing On Quality And Competitiveness

Http Www1 Pu Edu Tw Ylai Erp Dom 1042 Ppts S16 1042 Erp Dom Ap S16 Pdf

Operations Management Aggregate Planning Ppt Download

Aggregate Planning

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Ppt Aggregate Planning Powerpoint Presentation Free Download Id

0 件のコメント:

コメントを投稿